I.Full automatic flap disc back glue machine system

Ruison Technology over the years for abrasive applications automate a lot of research, with reference to foreign advanced automation equipment, combined with the actual situation of the domestic industry, abrasive flap wheel production, research design, development and manufacturing of leading domestic technology successfully hundred impeller automatically back melter, established a complete set of abrasive automatic molding equipment sales, training, service system. The machine is equipped with imported high-quality servo motor,through advanced automatic control system collection is a precision machinery, numerical control technology, automation technology and other disciplines and high-tech products, products of good dynamic performance, high precision, fast response, high stability,supported by dvanced automation gear, achieve higher productivity, it is coated abrasive flap wheel auto industry preferred adhesive models.

Ruison Technology has always insisted on the first-class management, product innovation and continuous improvement, the introduction of sophisticated machining equipment to ensure product quality, to help our customers reduce production and operation costs, improve production efficiency, automation and control the production process for customers to provide comprehensive services , high-performance products with industry insiders have also been affirmed.

Ruison automatic flap disc glue machine system comprising:

♦Professional CNC system

♦ Precision high-speed transmission

♦Smart thermostat gluing system

♦Precision pneumatic control, the robot cutting system

♦Hardware and software training

♦One year warranty

♦Free software upgrades for life

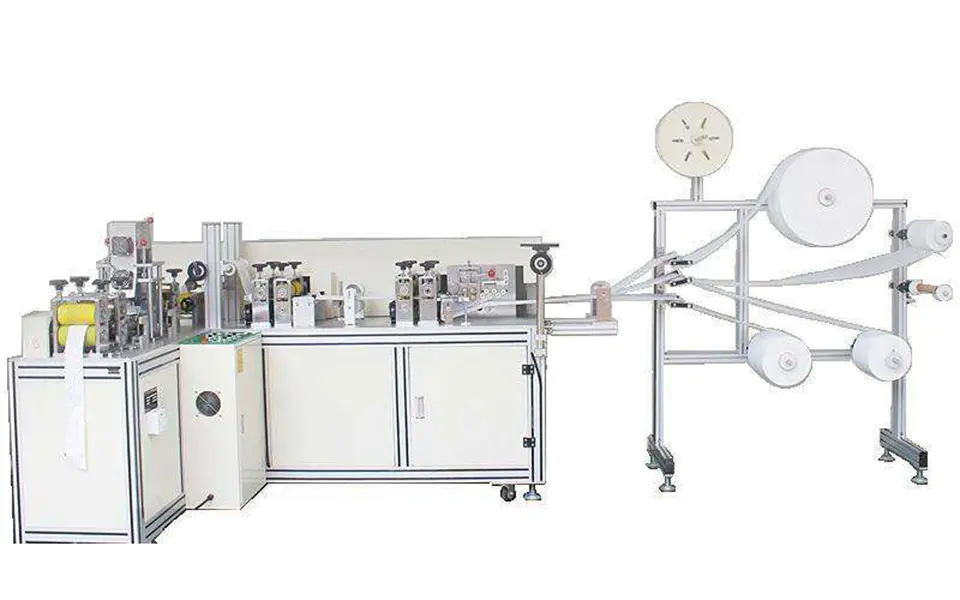

II.Machine photo

III.Technical datas

IV.Key configuration features

1.Mechanical systems: drive transmission components imported linear guide rail friction coefficient is small, high-speed servo motor configuration and reducer.

2.The world's leading engineering structural mechanics mechanical design, unique design, advanced and reasonable, selected high-quality alloy materials, professional CNC machining centers overall precision milling grinding machining, molding, solid and durable.

3.Holder bed by the after quenching, tempering aging strengthening thick-walled steel seamless welded, strong and stable without deformation.

4.New cantilevered table, unique design, can automatically grab a variety of different substrate materials, coupled with high-strength aluminum alloy material, solid and durable.

5.Pneumatic device uses high-precision drive mechanism, with advanced international standard installation, respond quickly and accurately, good wear resistance.

6.Professional brand electrical components and industrial control system fully functional, stable performance.

V.Machine operation features:

♦Use louver adhesive professional numerical control system, high degree of automation, automatic feeding set quantitative gluing, cutting one, easy to learn.

♦Use multi-station rotary turntable mechanism, converting station stable and smooth, precise positioning and high efficiency.

♦Glue system uses glue on the piston fluid PID control mode, to adapt to different materials glue, convenient and efficient.

♦Products used in the coating process imported photoelectric switch detects the presence or absence of the louvres, automatic filtering station no one hundred blades, stable and accurate.

♦Material utilization is high, the amount of adhesive, coating precision adjustable speed, easy operation.

♦Robot automatic loading and finished crawling precision, productivity is guaranteed.

♦Processing variety, adapt plastic, mesh cover, metal cover other substrate.

VI.Machine functions

A new generation of Ruison flap disc gum machine with a new design concept, the previous generation of products based on the integration and optimization of the components, so that the whole structure is more stable precision, effectively improve product stability and durability. Wang Feng flap wheel gum machine can automatically crawl flap wheel, matrix detection, quantitation coating, and finished under automatic, one hundred impeller finished product quality, quality control.

VII.Main parts:

Note: physical and picture may be slightly inconsistent in kind prevail.

Ruison Technology over the years for abrasive applications automate a lot of research, with reference to foreign advanced automation equipment, combined with the actual situation of the domestic industry, abrasive flap wheel production, research design, development and manufacturing of leading domestic technology successfully hundred impeller automatically back melter, established a complete set of abrasive automatic molding equipment sales, training, service system. The machine is equipped with imported high-quality servo motor,through advanced automatic control system collection is a precision machinery, numerical control technology, automation technology and other disciplines and high-tech products, products of good dynamic performance, high precision, fast response, high stability,supported by dvanced automation gear, achieve higher productivity, it is coated abrasive flap wheel auto industry preferred adhesive models.

Ruison Technology has always insisted on the first-class management, product innovation and continuous improvement, the introduction of sophisticated machining equipment to ensure product quality, to help our customers reduce production and operation costs, improve production efficiency, automation and control the production process for customers to provide comprehensive services , high-performance products with industry insiders have also been affirmed.

Ruison automatic flap disc glue machine system comprising:

♦Professional CNC system

♦ Precision high-speed transmission

♦Smart thermostat gluing system

♦Precision pneumatic control, the robot cutting system

♦Hardware and software training

♦One year warranty

♦Free software upgrades for life

II.Machine photo

III.Technical datas

| Product name | Full automatic flap disc back glue machine |

| Main machine size(mm) | 1200*1080*1300 |

| Voltage | 220V 50HZ |

| Total power | 0.8KW |

| Weight | 300kg |

| Glue volume | 15-20L |

| Glue quantity | 3~30g,can be adjusted,±0.1g |

| Efficiency | 1000 -1500pcs/hour |

| Backing diameter | Φ75mm |

| Backing material | Fiberglass,plastic,iron,etc |

| Motion Control System | Imported inverter+brand regulator+frequency motor |

| Glue system | Airtac cylinder |

IV.Key configuration features

1.Mechanical systems: drive transmission components imported linear guide rail friction coefficient is small, high-speed servo motor configuration and reducer.

2.The world's leading engineering structural mechanics mechanical design, unique design, advanced and reasonable, selected high-quality alloy materials, professional CNC machining centers overall precision milling grinding machining, molding, solid and durable.

3.Holder bed by the after quenching, tempering aging strengthening thick-walled steel seamless welded, strong and stable without deformation.

4.New cantilevered table, unique design, can automatically grab a variety of different substrate materials, coupled with high-strength aluminum alloy material, solid and durable.

5.Pneumatic device uses high-precision drive mechanism, with advanced international standard installation, respond quickly and accurately, good wear resistance.

6.Professional brand electrical components and industrial control system fully functional, stable performance.

V.Machine operation features:

♦Use louver adhesive professional numerical control system, high degree of automation, automatic feeding set quantitative gluing, cutting one, easy to learn.

♦Use multi-station rotary turntable mechanism, converting station stable and smooth, precise positioning and high efficiency.

♦Glue system uses glue on the piston fluid PID control mode, to adapt to different materials glue, convenient and efficient.

♦Products used in the coating process imported photoelectric switch detects the presence or absence of the louvres, automatic filtering station no one hundred blades, stable and accurate.

♦Material utilization is high, the amount of adhesive, coating precision adjustable speed, easy operation.

♦Robot automatic loading and finished crawling precision, productivity is guaranteed.

♦Processing variety, adapt plastic, mesh cover, metal cover other substrate.

VI.Machine functions

A new generation of Ruison flap disc gum machine with a new design concept, the previous generation of products based on the integration and optimization of the components, so that the whole structure is more stable precision, effectively improve product stability and durability. Wang Feng flap wheel gum machine can automatically crawl flap wheel, matrix detection, quantitation coating, and finished under automatic, one hundred impeller finished product quality, quality control.

VII.Main parts:

Note: physical and picture may be slightly inconsistent in kind prevail.