I.Ruison abrasive cloth slitting machine system

Ruison Technology over the years for abrasive applications automate a lot of research, with reference to foreign advanced automation equipment, combined with the actual situation of the domestic industry, abrasive flap wheel production, research design, development and manufacturing of leading domestic technology success emery cloth slitting machine , we established a complete set of abrasive automatic molding equipment sales, training, service system. The machine is equipped with famous brand frequency conversion motor, through advanced control system set, good dynamic performance products, high precision, fast response, high stability and efficiency to achieve higher production efficiency, industry is the preferred coated abrasive emery cloth slitting model.

Ruison Technology has always insisted on the first-class management, product innovation and continuous improvement, the introduction of sophisticated machining equipment to ensure product quality, to help our customers reduce production and operation costs, improve production efficiency, automation and control the production process for customers to provide comprehensive services , high-performance products with industry insiders have also been affirmed.

Ruison abrasive cloth slitting machine system comprising:

►Abrasive cloth slitting professional CNC system (intelligent type correction machine configuration, no such common model configuration)

►Precision transmission system.

►Precision pneumatic control system

►Automatic feeding assistance system: loading and unloading system, pump, pipe, etc.

►One year warranty (except supplies, the supplies, including cutter, sealing gasket, etc.)

II.Technical parameters

Key configuration features

1.International leading engineering machinery structural mechanics,advanced and reasonable,with well-chosen alloy and fine machined by advanced CNC center.

2.High strength welded body, tempering aging treatment, five-side milling drilling tapping,ensure rigidity and precision,stable and deformation.

3.Pneumatic device adopts high precision transmission mechanism.Coupled with advanced international installation method,fast react and with good wear resistance.

4.With professional brand electrical components and industrial control system, with full function and stable performance.

Equipment operation features

♦Using scissors cutting technology, precise mechanical correction device,with uniform slitting,easy to learn.

♦Well known brand variable frequency motor speed, adopt pneumatic automatic device to load jumbo roll,easy loading and unloading.

♦Rolling adopts straight pressing roller to ensure smooth rewinding.

♦High utilization of materials, abrasives cloth length and width can be precisely adjusted,with easy and convenient operation.

♦Main shaft and round knife adopt stepless change system, slitting speed can adjusted,rotation and reverse can be controlled.

♦Rewinding roller made of imported rubber,appearance machined by precision external grinder,with features of non-deformation and smooth rewinding.

♦Guider rollers adopts chrome-plating steel,each after balancing process.

Equipment functions

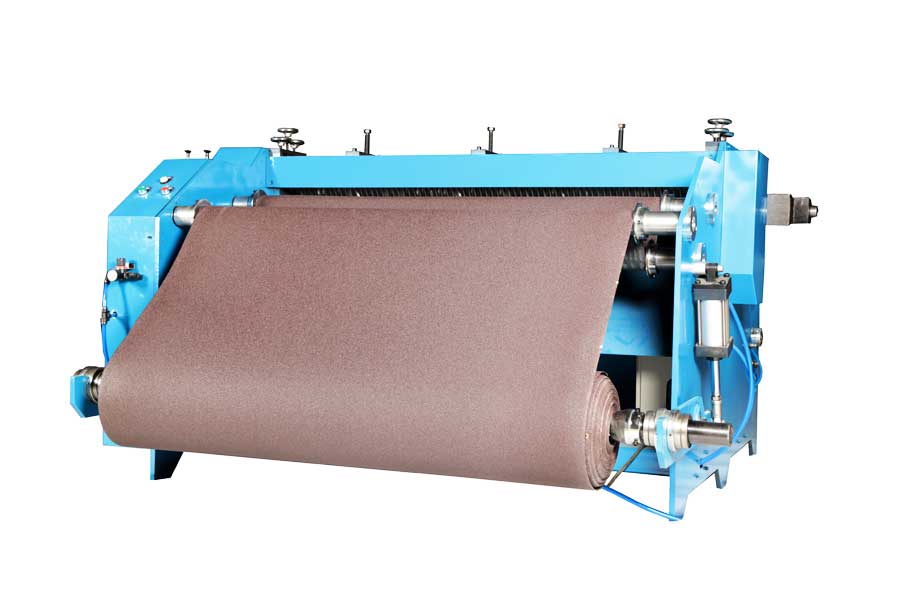

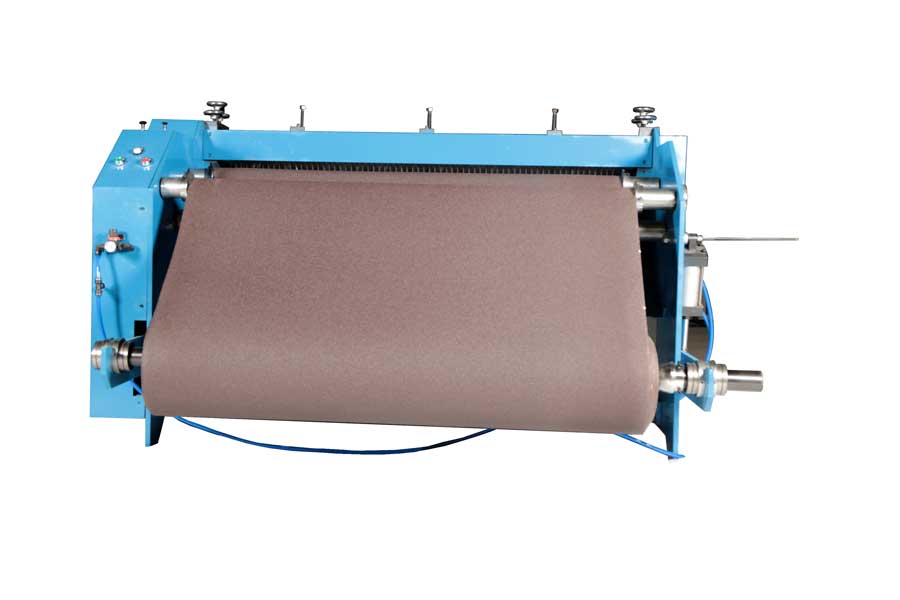

Based on the previous generation product, the Ruison new generation Abrasive cloth slitting machine optimize and integrate components with new design concept. It makes the whole structure more stable and durable, effectively and improving the product stability and durability. Fenghong abrasive cloth slitting machine is suitable for slitting jumbo rolls with 1.5 meter width and 50-120 meter length.Belt width can be customized according to customers’ requirements. With excellent performance and proven stability, Fenghong abrasive cloth slitting machine is your essential daily production equipment.

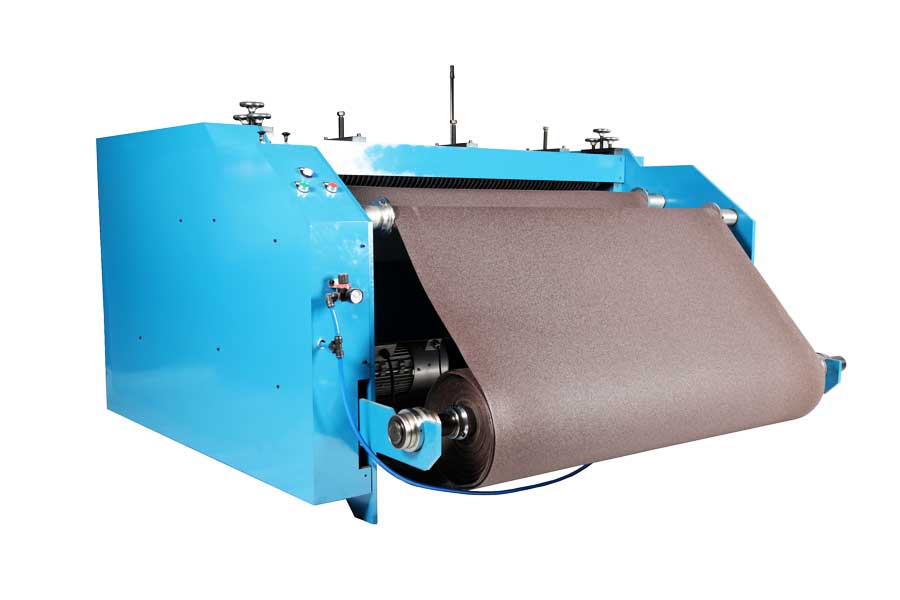

V.Machine details and belts sample.

Ruison Technology over the years for abrasive applications automate a lot of research, with reference to foreign advanced automation equipment, combined with the actual situation of the domestic industry, abrasive flap wheel production, research design, development and manufacturing of leading domestic technology success emery cloth slitting machine , we established a complete set of abrasive automatic molding equipment sales, training, service system. The machine is equipped with famous brand frequency conversion motor, through advanced control system set, good dynamic performance products, high precision, fast response, high stability and efficiency to achieve higher production efficiency, industry is the preferred coated abrasive emery cloth slitting model.

Ruison Technology has always insisted on the first-class management, product innovation and continuous improvement, the introduction of sophisticated machining equipment to ensure product quality, to help our customers reduce production and operation costs, improve production efficiency, automation and control the production process for customers to provide comprehensive services , high-performance products with industry insiders have also been affirmed.

Ruison abrasive cloth slitting machine system comprising:

►Abrasive cloth slitting professional CNC system (intelligent type correction machine configuration, no such common model configuration)

►Precision transmission system.

►Precision pneumatic control system

►Automatic feeding assistance system: loading and unloading system, pump, pipe, etc.

►One year warranty (except supplies, the supplies, including cutter, sealing gasket, etc.)

II.Technical parameters

| Product name | Abrasive cloth slitting machine |

| Main body size(mm) | 2200*2200*1200 |

| Electric condition | 380V 50HZ |

| Total power | 3.5KW |

| Weight | 1000KG |

| Slitting speed | 4-8minutes/meters |

| Abrasive cloth width | 1460MM |

| Total length | 50-120m |

| Belt width | 14mm-22mm |

| Motion Control System | Imported inverter+brand regulator+frequency motor |

| Feeding system | Airtac cylinder |

Key configuration features

1.International leading engineering machinery structural mechanics,advanced and reasonable,with well-chosen alloy and fine machined by advanced CNC center.

2.High strength welded body, tempering aging treatment, five-side milling drilling tapping,ensure rigidity and precision,stable and deformation.

3.Pneumatic device adopts high precision transmission mechanism.Coupled with advanced international installation method,fast react and with good wear resistance.

4.With professional brand electrical components and industrial control system, with full function and stable performance.

Equipment operation features

♦Using scissors cutting technology, precise mechanical correction device,with uniform slitting,easy to learn.

♦Well known brand variable frequency motor speed, adopt pneumatic automatic device to load jumbo roll,easy loading and unloading.

♦Rolling adopts straight pressing roller to ensure smooth rewinding.

♦High utilization of materials, abrasives cloth length and width can be precisely adjusted,with easy and convenient operation.

♦Main shaft and round knife adopt stepless change system, slitting speed can adjusted,rotation and reverse can be controlled.

♦Rewinding roller made of imported rubber,appearance machined by precision external grinder,with features of non-deformation and smooth rewinding.

♦Guider rollers adopts chrome-plating steel,each after balancing process.

Equipment functions

Based on the previous generation product, the Ruison new generation Abrasive cloth slitting machine optimize and integrate components with new design concept. It makes the whole structure more stable and durable, effectively and improving the product stability and durability. Fenghong abrasive cloth slitting machine is suitable for slitting jumbo rolls with 1.5 meter width and 50-120 meter length.Belt width can be customized according to customers’ requirements. With excellent performance and proven stability, Fenghong abrasive cloth slitting machine is your essential daily production equipment.

V.Machine details and belts sample.