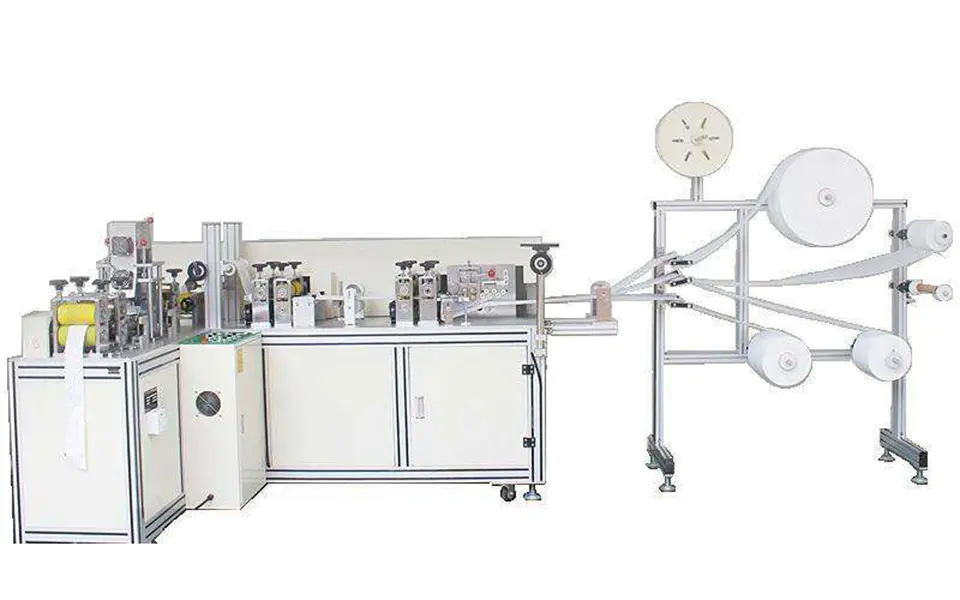

Flap disc packing system

Ruison technology over the years for abrasive applications automate a lot of research, with reference to foreign advanced automation equipment, combined with the actual situation of the domestic industry, abrasive flap wheel production, research design, development and manufacturing of leading domestic technology successfully hundred automatic plastic impeller machine, established a complete set of flap wheel automatic laminator sales, training, service system. The machine set precision machinery, automation technology and other disciplines in one, the products of good dynamic performance, high accuracy, fast response, high stability, with advanced automation gear, to achieve high efficiency packaging louvres, is abrasive industry The preferred packaging flap wheel models.

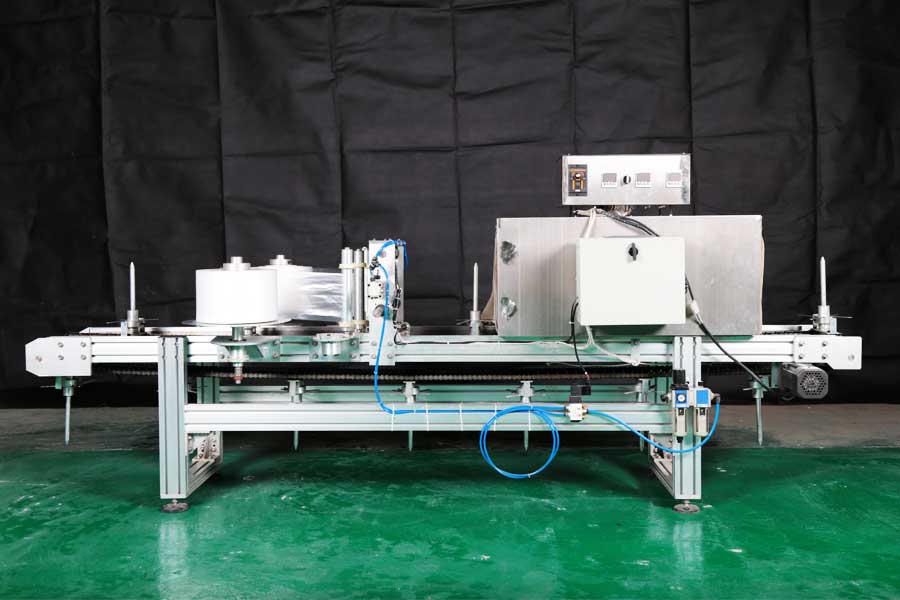

Shrink Packaging is one of the market is more advanced packaging methods, it is wrapped in shrink film outside of the product or package, after heating, the shrink film shrink bind tightly products or packaging, it shows that the appearance of goods, improve product the exhibition, increasing the sense of beauty and value. Meanwhile, the packaged items can be sealed, moisture, pollution prevention, and protect the goods from external shocks, especially when packing fragile items when you can prevent scattering of broken containers.

Just put the product manual automatic laminator, the machine automatically push things, sealing, shrink packaging series of acts, greatly reduce labor intensity, improve work efficiency, widely used in the packaging assembly line production, can be equipped with automated packaging line use (please consult Ruison engineering and technical personnel).

Ruison Technology has always insisted on the first-class management, product innovation and continuous improvement, the introduction of sophisticated machining equipment to ensure product quality, to help our customers reduce production and operation costs, improve production efficiency, automation and control the production process for customers to provide comprehensive services , high-performance products with industry insiders have also been affirmed.

I.Ruison full automatic flap disc packing system includes:

♦Precision Transmission

♦Smart thermostat system

♦ Precision pneumatic control system

♦Machine training

♦One-year warranty (except consumables parts)

II.Technical datas

III.Key configuration features:

1.The world's leading structural engineering mechanics mechanical design, advanced and reasonable, selected high-quality alloy materials, professional CNC machining centers overall precision milling grinding machining, molding, solid and durable.

2.The high-quality transmission parts reducer, micro-displacement response can transmit accurate.

3.The pneumatic system uses a brand of high precision pneumatic means international standard installation, respond quickly and accurately, good wear resistance.

4.The new chain-type table, the card can be installed in many different models of the base, coupled with high-strength aluminum alloy material, solid and durable.

5.Professional brand electrical components and industrial control system fully functional, stable performance.

IV.Machine operation features:

♦Adopts special numerical control system for flap disc packing,with high automation grade,integrated with constant temperature heating,quantitative cutting and automatic packing,easy to learn.

♦Rotating multiple working plate device,working plate transmission is stable and fluent.With precise positioning and high efficiency.

♦During packing,imported photoelectric switch can detect if flap disc loaded.Vacant pole can be automatically detected.

♦Packing film length can be precisely adjusted,with high rate of film utilization,easy and convenient operation.

♦Adopts "Ruison Only" digital temperature controller, with PID function inside, sealing knife temperature is extremely sensitive and accurate, can be set at will, effectively prevent false packaging

♦Transmission part adopts powerful DC motor, stepless speed regulation, high loading rate, can work continuously for a long time, stable and reliable operation.

V.Main functions

New generation Ruison flap dsic packing machine adopts brand new design concept,many parts were optimized compared with former generation,the whole structure is more precise and more stable,thus flap disc stability and durability is effectively improved.Fenghong flap disc packing machine can detect backing, The function of heating and thermostat Precise cutting heat shrinkable film automatic packaging, packaging Flap disc quality is very good and under control.

VI.Main parts and packing samples

Ruison technology over the years for abrasive applications automate a lot of research, with reference to foreign advanced automation equipment, combined with the actual situation of the domestic industry, abrasive flap wheel production, research design, development and manufacturing of leading domestic technology successfully hundred automatic plastic impeller machine, established a complete set of flap wheel automatic laminator sales, training, service system. The machine set precision machinery, automation technology and other disciplines in one, the products of good dynamic performance, high accuracy, fast response, high stability, with advanced automation gear, to achieve high efficiency packaging louvres, is abrasive industry The preferred packaging flap wheel models.

Shrink Packaging is one of the market is more advanced packaging methods, it is wrapped in shrink film outside of the product or package, after heating, the shrink film shrink bind tightly products or packaging, it shows that the appearance of goods, improve product the exhibition, increasing the sense of beauty and value. Meanwhile, the packaged items can be sealed, moisture, pollution prevention, and protect the goods from external shocks, especially when packing fragile items when you can prevent scattering of broken containers.

Just put the product manual automatic laminator, the machine automatically push things, sealing, shrink packaging series of acts, greatly reduce labor intensity, improve work efficiency, widely used in the packaging assembly line production, can be equipped with automated packaging line use (please consult Ruison engineering and technical personnel).

Ruison Technology has always insisted on the first-class management, product innovation and continuous improvement, the introduction of sophisticated machining equipment to ensure product quality, to help our customers reduce production and operation costs, improve production efficiency, automation and control the production process for customers to provide comprehensive services , high-performance products with industry insiders have also been affirmed.

I.Ruison full automatic flap disc packing system includes:

♦Precision Transmission

♦Smart thermostat system

♦ Precision pneumatic control system

♦Machine training

♦One-year warranty (except consumables parts)

II.Technical datas

| Product name | Flap disc packing machine |

| Size(mm) | 3200*1000*1500 |

| Weight(kg) | 280 |

| Voltage | 220V 50HZ |

| Power | 6KW |

| Temperature | 0-220 |

| Packing specs | Φ75mm~Φ180mm 、 T27/T29 |

| Efficiency | 8-12packages/minute |

| Film | PE, 40-50μm |

| Packing quantity | 5-25pics/set |

| Packing object | Cutting wheel,flap disc,etc |

| Motion Control System | Brand reducer |

| Pneumatic system | Airtac valve cylinder SMC |

| Temperature Control System | Shrinking temperature 180-200,Cutter temperature 125-135 |

III.Key configuration features:

1.The world's leading structural engineering mechanics mechanical design, advanced and reasonable, selected high-quality alloy materials, professional CNC machining centers overall precision milling grinding machining, molding, solid and durable.

2.The high-quality transmission parts reducer, micro-displacement response can transmit accurate.

3.The pneumatic system uses a brand of high precision pneumatic means international standard installation, respond quickly and accurately, good wear resistance.

4.The new chain-type table, the card can be installed in many different models of the base, coupled with high-strength aluminum alloy material, solid and durable.

5.Professional brand electrical components and industrial control system fully functional, stable performance.

IV.Machine operation features:

♦Adopts special numerical control system for flap disc packing,with high automation grade,integrated with constant temperature heating,quantitative cutting and automatic packing,easy to learn.

♦Rotating multiple working plate device,working plate transmission is stable and fluent.With precise positioning and high efficiency.

♦During packing,imported photoelectric switch can detect if flap disc loaded.Vacant pole can be automatically detected.

♦Packing film length can be precisely adjusted,with high rate of film utilization,easy and convenient operation.

♦Adopts "Ruison Only" digital temperature controller, with PID function inside, sealing knife temperature is extremely sensitive and accurate, can be set at will, effectively prevent false packaging

♦Transmission part adopts powerful DC motor, stepless speed regulation, high loading rate, can work continuously for a long time, stable and reliable operation.

V.Main functions

New generation Ruison flap dsic packing machine adopts brand new design concept,many parts were optimized compared with former generation,the whole structure is more precise and more stable,thus flap disc stability and durability is effectively improved.Fenghong flap disc packing machine can detect backing, The function of heating and thermostat Precise cutting heat shrinkable film automatic packaging, packaging Flap disc quality is very good and under control.

VI.Main parts and packing samples