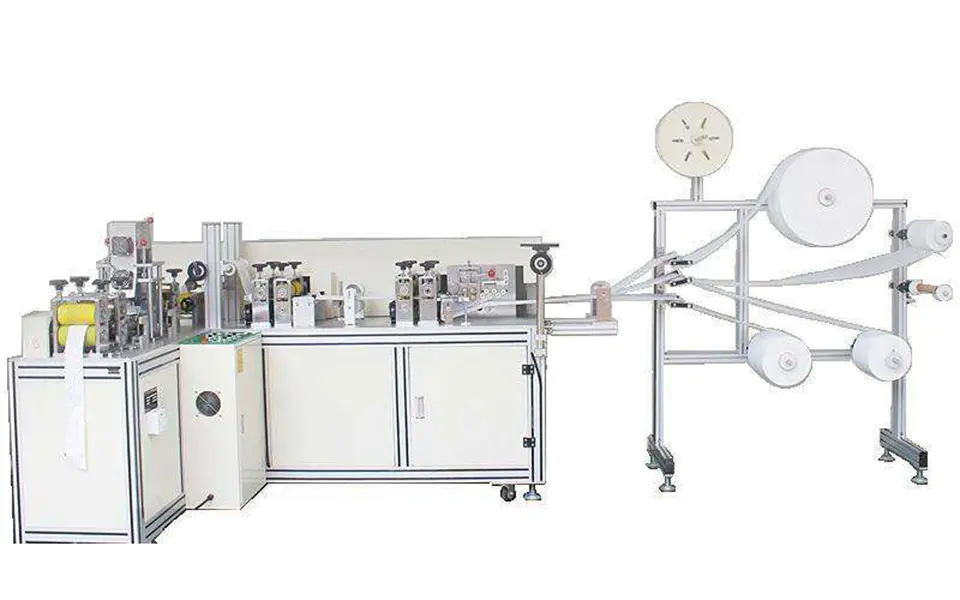

Automatic Mask Machine Overview:

The fully automatic one-to-two mask machine is connected with a mask body machine and a diverter, which is connected through the diverter and the earband fusion splicer. After the machine starts, the mask body machine produces the product and transfers it to the conveyor On the shunt machine, the earmuff part is welded by transferring the mask from the shunt machine to the earband welding machine to complete a complete mask finished product. The entire process realizes a fully automated production process without manual operation, that is, one main machine and two ears. Belt-connected, the output can reach 90-120 pcs/ min.

Automatic Mask Machine Features:

1. Fully automatic output. The mask body is automatically acquired by the ear band machine, which reduces labor costs and reduces the possibility of interference.

2. From the production of the mask body to the ear band, the nose bridge strip is melted, and the ear band is spot welded. It is fully automated and formed at one time.

3. Full-automatic one-to-two mask machine plane mask folding can be adjusted according to your own needs.

4. The machine adopts computer programmed control and photoelectric detection to improve the stability of the machine and reduce the failure rate of the machine.

5. This machine adopts variable frequency control to accurately control production efficiency and production speed. Users can also adjust the production speed according to their actual conditions.

Automatic Mask Machine Welding Principle:

The air source power provided by the air compressor is guided into the cylinder for linear reciprocating motion. The gas is compressed by the piston in the air compressor cylinder to increase the pressure. The gas supply from the side of the piston gathers energy to generate air pressure. The air pressure pushes the piston to produce thrust. The surface of the titanium alloy welding head and two ultrasonic welding heads rub against each other (tens of thousands of high-frequency vibrations per second) to form a molecular layer Of fusion.

Automatic Mask Machine Material:

imported cylinder, imported servo motor, stepping motor, ultrasonic, human-machine interface (touch screen), aluminum alloy structure, photoelectric detection raw material, high-quality steel and aluminum concentrate, precision machining through CNC, Beautiful appearance, no rust, more durable.

Automatic Mask Machine Components:

The main components of the equipment are imported cylinders, imported servo motors, imported stepper motors, ultrasonic waves, photoelectric detection raw materials, aluminum alloy structures, high-quality steel and aluminum concentrates, which have undergone more than 3,000 procedures over 1020 hours. It ensures that the customer has high stability and low failure rate in the process of using the equipment. It is assembled after repeated testing at each assembly procedure.

Automatic Mask Machine Parameters:

| Product size | 7000*6000*2000 | Material | Alloy aluminum profile + section steel |

| Power | 11KW | Control mode | Imported PLC+ touch screen |

| Weight | 2200KG | Operating system | Chinese/English |

| Production efficiency | 90-120PCS/min | Operator Number | one worker multiple machine |

| Masks structure | Line type outer ear | The number of layer | Three layer |

| Mask size | 175*95 | Mask fold number | Accord to client’s request |

Automatic Mask Machine To Produce Finished Masks:

Main Function Of Automatic Mask Machine:

The production line of this equipment is mainly composed of a main body machine, a flap conveying line and two ear band welding machines. After the main body machine outputs the mask body, the mask body sheet is conveyed to the turning mechanism by a conveyor belt structure. The reversing mechanism flips the mask sheet onto the conveyor belt connected to the ear band machine, and then conveys the mask sheet to the front mask plate of the ear band machine through the conveyor belt. The ear band is put in place, and the ear band welding of the mask is completed by the ear band machine, thereby completing the production of a flat outer ear mask product.As shown in the figure below, the whole line is a one-for-two structure:

This line adopts PLC and touch screen control. The main conveyor belt is transported by single-phase motor.

Automatic Mask Machine Equipment List:

|

No. |

Part Name |

Quantity |

Note |

|

1 |

SS outer non-woven fabric / filter non-woven fabric / SS inner non-woven fabric unwinding mechanism |

3set |

|

|

2 |

Nose bridge strip unwinding mechanism |

1set |

|

|

4 |

Bridge of the nose strip drive, cutting mechanism |

1set |

Width:3-7mm |

|

5 |

Fabric folding mechanism |

1set |

|

|

6 |

Seam sealing mechanism |

1set |

Double side |

|

8 |

Fabric fan folding mechanism |

2 set |

|

|

9 |

Weld side seam mechanism |

1set |

|

|

10 |

Roll sealing mechanism |

1 |

|

|

11 |

Transfer line |

1pcs |

|

|

12 |

Shunt institutions |

1set |

|

|

13 |

Ear band welder mechanism |

1set |

|

|

14 |

Blanking line |

1pcs |

|

|

15 |

operating system |

1set |

|

|

16 |

operation panel |

1set |

|

1. Mask body production machine

2. mask rewinding machine

3. mask ear band welding machine

Automatic Mask Machineb Use Environment:

Working temperature: 0 ~ 40 ℃ Humidity: 5 ~ 38% HR No flammable gas, corrosive gas No dust in workshop (not less than 100,000)

Automatic Mask Machineb Delivery Instructions:

Follow-up delivery arrangements: Provide online technical support. After the epidemic, you can arrange for after-sales service to provide technical services.