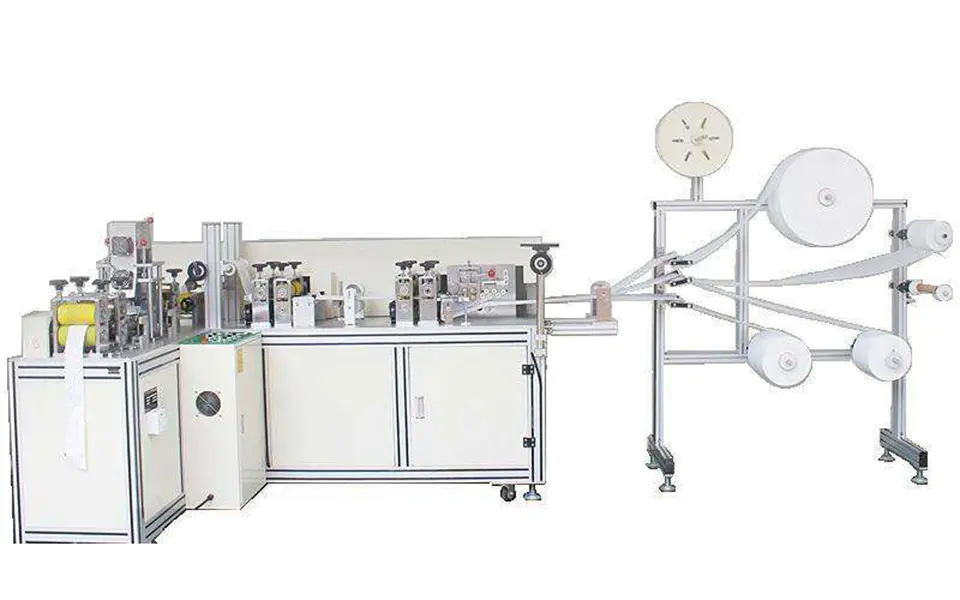

- RSWQ-180 full-auto flap disc machine is the fully automated equipment to produce flap disc, which can realize autatically load backing pad, detection of backing pad, quantitative glue, blanking and slide arranging, shaping and automation equipment of the products automatically.

The Performance and Characteristics of RSWQ-180 full automatic flap disc machine:

Adopt PLC to control human machine interface and the automaticity is of great degree. One person can complete the whole operation , thus saving labor and cost.

- The production efficiency is high with 600 to 800 pieces per hour.

The utilization of raw material is great and the binder and abrasive belt can be set freely.

The defective rate is as low as 0% after adjusting the machine.

A multi-station rotary turntable mechanism is adopted, which leads to stable station conversion, precise positioning and high efficiency.

The thickness of the matrix can be detectable, and gluing system adopts internal water circulation constant temperature control system, which provides gluing system the temperature, making it convenient, efficient, fast and stable.

The product can take optoelectronic switch to test the existence of engine body and gauze during the process of arranging cards, and it is stable and precise as well saving time.

Angles of blades on the machine head can be adjusted. Calibrated scales are equipped for the translation in the adjustment of the machine, and the machine head can be accurately and effectively adjusted according to the display parameters. Guide rails are installed directly inside the machine head to avoid dust and ash.

Technical data and price for RSWQ-180 full automatic flap disc machine: -

Specification of products Φ100-180mm,T27/T29,1blade or 2blades,blade width 11-35mm Manufacturing speed 6000-8000pcs/10hours Backing pad Fiber glass or plastic Power Total 6kw,3phase,380v,50hz Power source of the overall machine Pneumatic and electric Glue pump load 280kg Glue system AirTac air cylinder and SMC balance control valve Glue-spread volume 4-30g(±0.02g) Product row pieces count it could be arranged blades at any point in 360 angle Operator needed 1 Packing dimension 1.6x1.4x1.65m(main machine)+ 0.9x1.25x1.8m(glue system) Packing volume 5.7CBM Gross weight 1000kg Net weight 800kg