Ruison technology over the years for abrasive applications automate a lot of research, with reference to foreign advanced automation equipment, combined with the actual situation of the domestic industry, abrasive flap wheel production, research design, development and manufacturing of leading domestic technology successfully hundred impeller molding machine , we established a complete set of flap wheel molding machine sales, training, service system. The machine is equipped with imported high-quality servo motor, through advanced automatic control system collection is a precision machinery, numerical control technology, automation technology and other disciplines and high-tech products, products of good dynamic performance, high precision, fast response, high stability, supported by advanced automation gear, to achieve high efficiency louvres molding is the preferred coated abrasive flap wheel molding equipment industry.

Ruison technology has always insisted on the first-class management, product innovation and continuous improvement, the introduction of sophisticated machining equipment to ensure product quality, to help our customers reduce production and operation costs, improve production efficiency, automation and control the production process for customers to provide comprehensive services , high-performance products with industry insiders have also been affirmed.

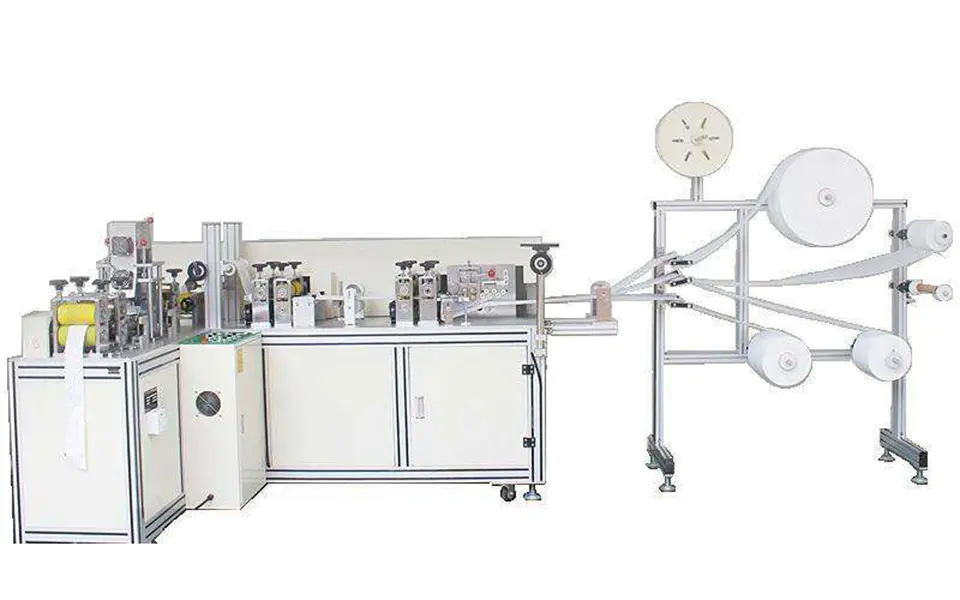

Ruison semi-automatic flap disc machine system include:

♦Flap disc professional CNC system

♦Precision transmmission system

♦smart thermostat gluing system

♦Precision pneumatic control system

♦Forming auxiliary system

♦Hardware and software training

♦One year warranty (except supplies, the supplies, including cutter, sealing gasket, etc.)

♦Free software upgrades for life

III.Technical datas

IV.Key configuration features

1.Mechanical system: transmission components imported linear guide rail, high-speed servo motor, reducer, you can trace the displacement response, accurate feeding, to closed-loop control length encoder system consisting of the source file to make finished products a perfect match.

2.International leading mechanical structure design,advanced and reasonable,with well-chosen alloy and fine machined by advanced CNC center.

3.The stent bed by hardened, aging strengthening tempered thick-walled seamless steel tubes welded, strong and stable without deformation.

4.The new turret table, original design, the card can be installed in many different models of the base, coupled with high-strength aluminum alloy material, solid and durable.

5.Dust Control System design is reasonable, imported linear guide as to the body's internal, effective protection of the transmission parts, to ensure the smooth operation of equipment.

6.The pneumatic device uses high-precision drive mechanism, the international standard installation, respond quickly and accurately, good wear resistance.

7.Professional brand electrical components and industrial control system fully functional, stable performance.

8.This series model has a number of patents, the industry leading technology innovation, leading industry standards, is currently the most cost-effective and abrasive industry's most high-tech automated processing equipment.

9.Machine operation features:

♦Adopts special numerical control system for flap disc production,with high automation grade,integrated with glue dispensing,flaps cutting and setting and shaping,easy to learn and operate.

♦Rotating multiple plate device,stable and fluency working plates transposition,with precise positioning and high efficiency.

♦Glue feeding system adopts PID control mode.Glue pump structure is very reasonable,adapts to different glue.

♦During flap setting,adopts imported photoelectric switch to detect backing and belt.Backing vacant working plate and backing without glue coated can be automatically detected and filtered with stable precision.

♦Flap setting angle and flap length can be precise adjusted,with easy and convenient operation

♦Raw material can be fully utilized,glue coated quantity,flap length and quantity can be adjusted

♦After setting the machine parameters, yield none in the industry.

♦Robot automatic loading and finished products, quality control, production capacity is guaranteed. (Automatic machine has this feature)

♦Processing varieties rich addition to the traditional four inches to seven inches, but can also be processed products such as two-piece.

V.Machine main functions

New generation Ruison semi automatic flap disc machine adopts brand new design concept,many parts were optimized compared with former generation,the whole structure is more precise and more stable,thus flap disc stability and durability is effectively improved.Fenghong semi automatic flap disc machine can detect backing, quantitatively feeding,flap cutting and setting,shaping Flap disc quality is very good and under control.

VI.Main parts and spare parts photos

VII.Flap disc samples

Ruison technology has always insisted on the first-class management, product innovation and continuous improvement, the introduction of sophisticated machining equipment to ensure product quality, to help our customers reduce production and operation costs, improve production efficiency, automation and control the production process for customers to provide comprehensive services , high-performance products with industry insiders have also been affirmed.

Ruison semi-automatic flap disc machine system include:

♦Flap disc professional CNC system

♦Precision transmmission system

♦smart thermostat gluing system

♦Precision pneumatic control system

♦Forming auxiliary system

♦Hardware and software training

♦One year warranty (except supplies, the supplies, including cutter, sealing gasket, etc.)

♦Free software upgrades for life

III.Technical datas

|

Semi-automatic flap disc machine |

|

|

Model |

RSW-125/180 |

|

Main machine size(mm) |

1300*800*1800 |

|

Glue system size(mm) |

1100*650*1500 |

|

Output |

800-1000pcs/hour |

|

Belt frame size(mm) |

1000*400*1450 |

|

Voltage |

380V 50HZ |

|

Total power |

5~7KW |

|

Glue pump |

280KG/ 30KG |

|

Glue coated |

3-30g(can be adjusted)±0.1g |

|

Flap quantity |

Can be set at any angle of 360° |

|

Backing size |

Φ75mm~Φ180mm 、 T27/T29 |

|

Backing material |

Fiber glass or plastic |

|

Belt width |

Dual flaps,flap width 11-35mm |

|

Flap length |

14mm-22mm |

|

Control system |

Imported servo motor+regulator+linear guide |

IV.Key configuration features

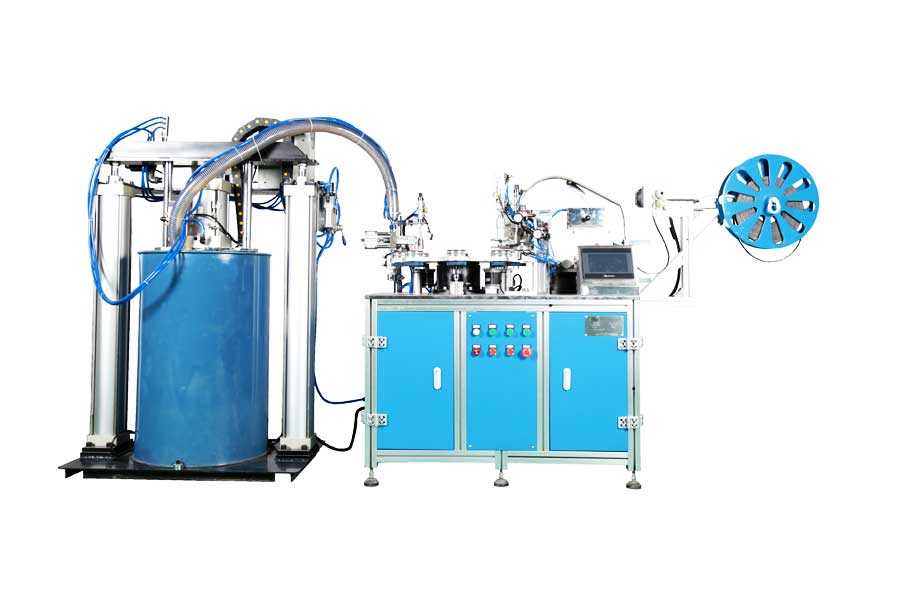

1.Mechanical system: transmission components imported linear guide rail, high-speed servo motor, reducer, you can trace the displacement response, accurate feeding, to closed-loop control length encoder system consisting of the source file to make finished products a perfect match.

2.International leading mechanical structure design,advanced and reasonable,with well-chosen alloy and fine machined by advanced CNC center.

3.The stent bed by hardened, aging strengthening tempered thick-walled seamless steel tubes welded, strong and stable without deformation.

4.The new turret table, original design, the card can be installed in many different models of the base, coupled with high-strength aluminum alloy material, solid and durable.

5.Dust Control System design is reasonable, imported linear guide as to the body's internal, effective protection of the transmission parts, to ensure the smooth operation of equipment.

6.The pneumatic device uses high-precision drive mechanism, the international standard installation, respond quickly and accurately, good wear resistance.

7.Professional brand electrical components and industrial control system fully functional, stable performance.

8.This series model has a number of patents, the industry leading technology innovation, leading industry standards, is currently the most cost-effective and abrasive industry's most high-tech automated processing equipment.

9.Machine operation features:

♦Adopts special numerical control system for flap disc production,with high automation grade,integrated with glue dispensing,flaps cutting and setting and shaping,easy to learn and operate.

♦Rotating multiple plate device,stable and fluency working plates transposition,with precise positioning and high efficiency.

♦Glue feeding system adopts PID control mode.Glue pump structure is very reasonable,adapts to different glue.

♦During flap setting,adopts imported photoelectric switch to detect backing and belt.Backing vacant working plate and backing without glue coated can be automatically detected and filtered with stable precision.

♦Flap setting angle and flap length can be precise adjusted,with easy and convenient operation

♦Raw material can be fully utilized,glue coated quantity,flap length and quantity can be adjusted

♦After setting the machine parameters, yield none in the industry.

♦Robot automatic loading and finished products, quality control, production capacity is guaranteed. (Automatic machine has this feature)

♦Processing varieties rich addition to the traditional four inches to seven inches, but can also be processed products such as two-piece.

V.Machine main functions

New generation Ruison semi automatic flap disc machine adopts brand new design concept,many parts were optimized compared with former generation,the whole structure is more precise and more stable,thus flap disc stability and durability is effectively improved.Fenghong semi automatic flap disc machine can detect backing, quantitatively feeding,flap cutting and setting,shaping Flap disc quality is very good and under control.

VI.Main parts and spare parts photos

VII.Flap disc samples